Description

1/2 tph*

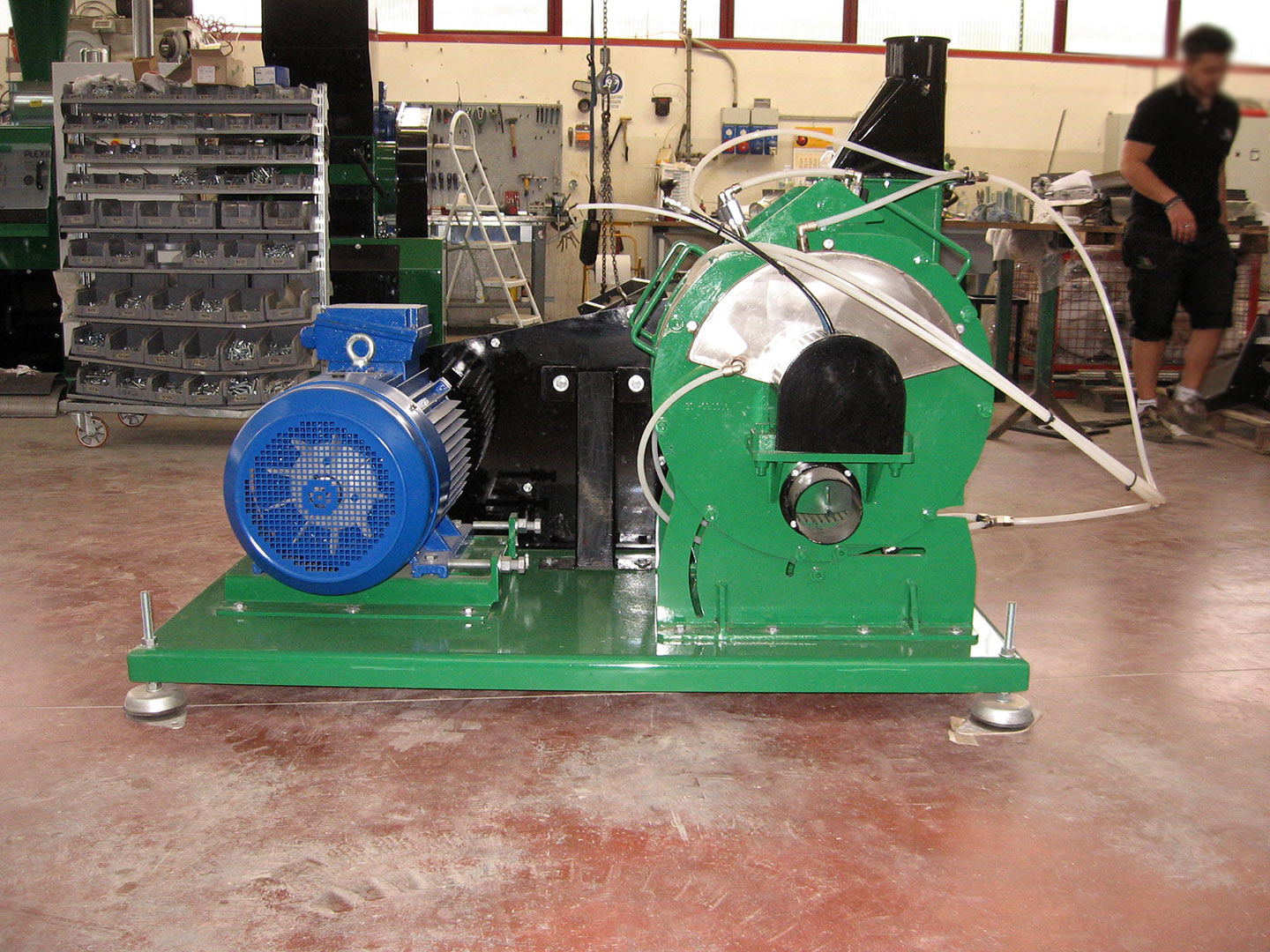

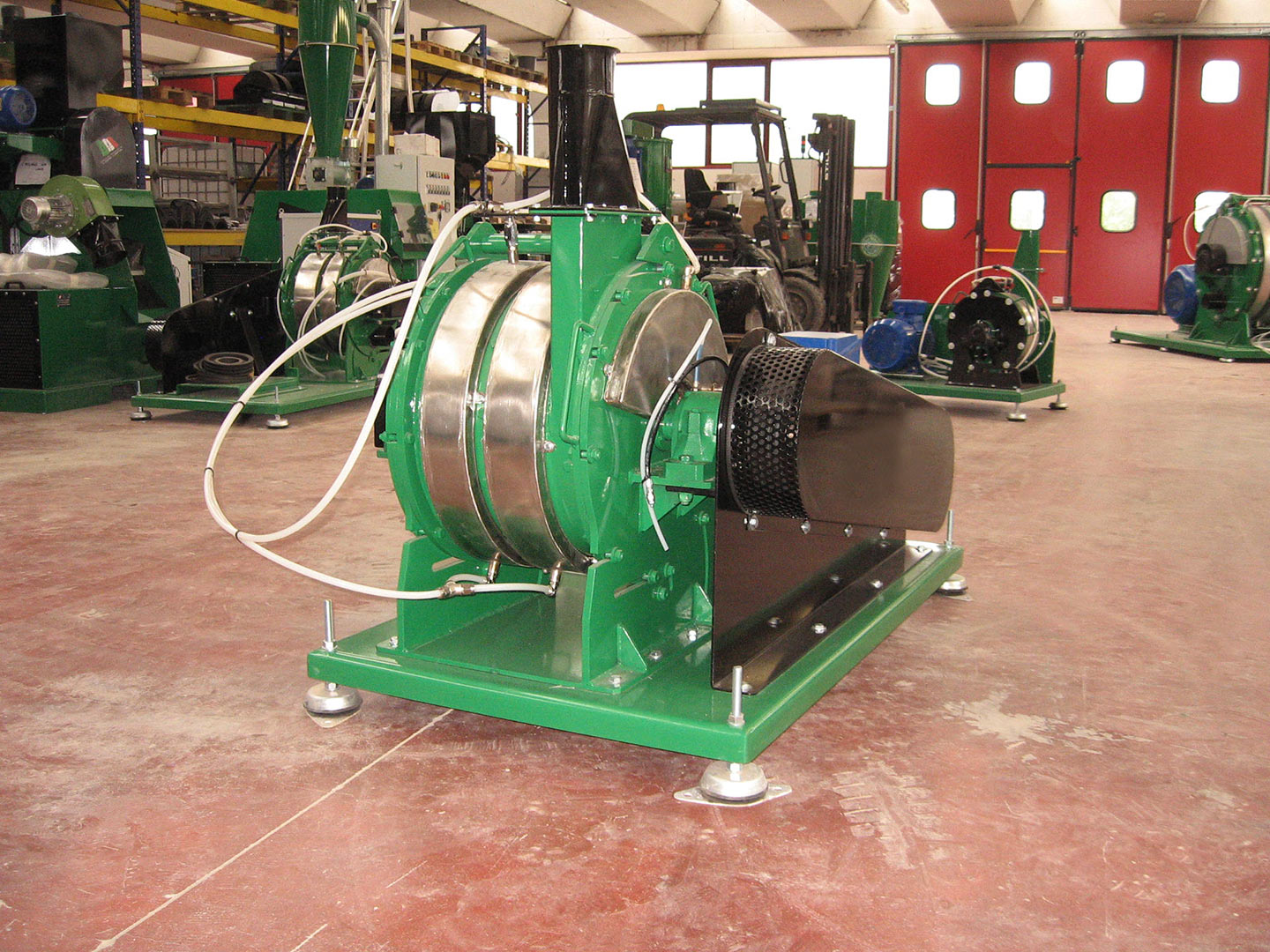

The CMTM-500 turbo mill is designed to grind rigid and semi rigid materials into a fine particle sizes smaller than 1/16″ in diameter.

- Capacity of the machine is determined by the rigidity of the materials and particle size.

- 30hp TEFC 360/230/460 3ph electric motor (40hp and 50hp available for more throughput)

- Carbon steel plate body.

- Easily interchangeable steel wear plates and beater knives.

- Clam-shell design for easy opening.

- Designed and plumbed with water-cooling chambers for reduced heat and maximum production efficiency.

(Priced with 30hp option, throughput of up to 700lbs/hr)

NOTE: A blower, cyclone and air-lock valve are required in order to pull the material thru the Turbo Mill.

OPTIONAL:

The following options are available at an- l cost.

- Water Chiller (keeps cold water flowing thru the stainless chambers reducing the heat caused by the friction.

- VFD (for speed control)

- 40hp Motor *up to 800lbs/hr +$1,000

- 50hp Motor *up to 1000lbs/hr +$1,500

(Non-openable model available for 15% less).

NOTE: A blower, cyclone and air-lock valve are required in order to pull the material thru the Turbo Mill.