Over 11 million metric tons of lithium-ion batteries are expected to reach the end of their service lives between now and 2030, with the US alone estimated to have 80 metric kilotons of Li-ion batteries to recycle by the end of this decade. With less than 5% of Li-ion batteries currently being recycled and 80% of lithium mining expected to be solely used for Li-ion batteries by 2030, there is incredible opportunity in deploying proven solutions to mitigate raw material demands and shortages.

![]() Watch all of our machines in action on YouTube.

Watch all of our machines in action on YouTube.

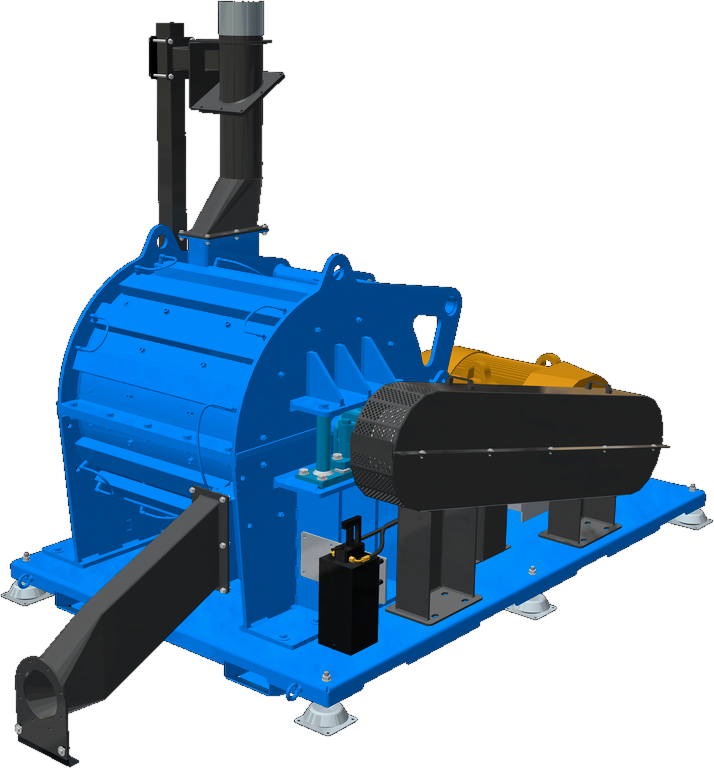

It began with a proof of concept. Before creating a processing line to viably and efficiently extract black mass from batteries, it was a necessary to do it on a small scale. Our first experience was with faulty e-cigarettes. Using our knowledge from hundreds of customized processing lines that we have built, a small scale trial was made to confirm feasibility of this process. Since then, we have scaled equipment offering to an industrial scale where we now provide consultation, equipment, and commissioning to anyone who needs a recycling solution for Li-ion batteries.

It is well known that lithium, nickel, manganese, and cobalt are highly expensive and resource demanding, the recycling market is still young and few have deployed industrial-scale recovery systems for these batteries. Cable Management leads the way with innovative solutions to maximize recovery and fill the gap to combat the upcoming surge of depleted Li-ion batteries set to hit the market by 2030.

Our processes make a product that is ready for a pyrometallurgical or hydrometallurgical process. Our engineers work with you to tailor-build battery recycling lines or integrate our systems into your current plant to provide you with the best results.