Take Back Control

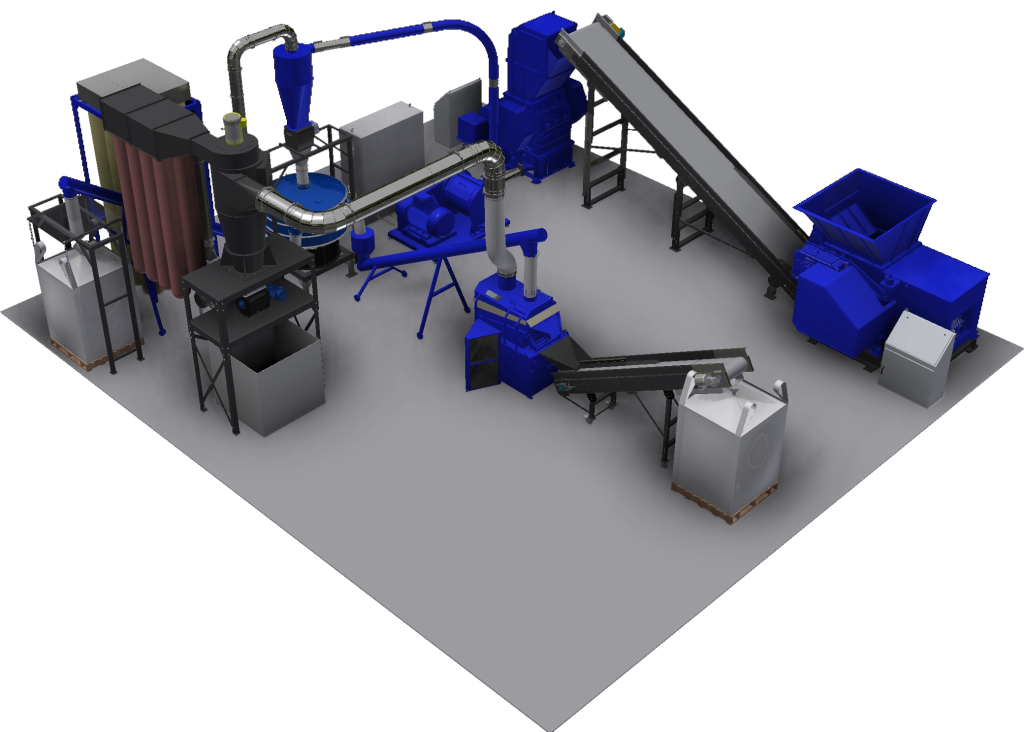

Be in charge of your processing equipment, increasing recovery, yields, throughput, and longevity with quality-built machinery.

Manage Your Materials

Improve your recycling capabilities with full confidence by finding the right solution for each application, specification, and purity need.

Get Peace of Mind

Harness the expertise gained from hundreds of different non-ferrous recovery system integrations and decades of industry experience.

Getting the Wrong Recycling Partner is Costly

Choosing your non-ferrous recycling partner is the biggest decision you will make in your processing equipment business. But, the incorrect choice has very real consequences.

- Unreliable machinery that gives you inconsistent results

- Further purchases to make up for improper equipment

- Unserviceable and difficult-to-maintain machinery

- Unnecessary downtime that impacts your profits

- End-products and yields that leave money on the table

You Need a Recycling Company Who Knows Non-Ferrous Recovery

Your worries should be relieved when choosing a recycling partner, not increased. Working with our team at Cable Management is the long-term move that will help you and your company succeed.

You can expect:

- Expert consulting from decades of experience

- Honest evaluations of your needs

- The right equipment for the job

- Ongoing personable, fast and friendly service

- Wear-items and critical replacement parts in stock

We make it simple to get you the right equipment for your challenges, goals, and budget

Fill Out Our Free Request a Quote Form

Tell us about your non-ferrous recycling needs and relax knowing we will never contact you with unnecessary calls or emails.

Assess Your Options With a Professional

One of our experts will reach out to you within 5 business days and conduct a thorough assessment and review the potential solutions with you.

Choose the Best Fit Solution for You

We will educate you on all your machinery options so you are empowered to make informed decisions for your unique needs.

Lean on Cable Management’s Expertise

We are focused on your long-term success and partnership which is why we are always available for troubleshooting, questions, and help.

Knowledge & Resources

- How Do You Deal with All of the Dust?One question we often get is, “How do you handle all the dust when recycling?” To that, we usually joke, “What dust?” But seriously, there is a lot of dust involved in recycling materials. The daily dust you deal with while chopping gets collected by the dust collector or bag…

- What Size Granulator Screen Do I Need?When you are not using a shredder, turbo, or delamination mill in your processing system, the right granulator screen to use can vary a lot. In this case, where you are just using a granulator straight into an air table, there will be more variation in your screen size needs.…

- How Do You Process Steel-BX or Aluminum-BX?We are going to discuss the differences between steel BX and aluminum BX, also known as MC cable. There are various terms used, but these are the most common. We process these cables in two different ways, although they go through similar equipment, not all steps are the same. Traditionally,…

- The Difference Between Wet & Dry SeparationWhat are the differences between wet and dry separators? Well, one is dry, and the other is wet. Dry separators use air, which is blown from its bottom compartment, where the blower is, and up through the angled deck above. The heavier materials move to the front and the lighter…

- How To Process: Auto Harness WireWhile sometimes mixed up, there are distinctions between auto harness wire, auto shredder residue, and auto shredder residue wire, and specific equipment needed for each. A lot of people ask about suitable equipment, assuming what works for one can work for the other, but the right equipment for the right…

- How Do You Separate Copper & Aluminum?A common question in the recycling industry is about the separation of copper and aluminum and how it is possible. The reason is because of their different densities, however, achieving this separation is not always straightforward, and here is why: Imagine an air table, with an opening on top for…

- How Does A Cyclone Separator Work?We are delving into how a cyclone separator operates. For those already familiar, you might not immediately think of a cyclone as a separator, but it is. The primary function is to segregate air streams—clean from dirty. Imagine everything as an airstream. One possible configuration is the cyclone under pressure,…

- Is It Worth Stripping Wire?We are going to tackle the question: is it worth stripping your wire? Often, scrappers come in wondering about insulated vs bare wire. The factor they overlook is recovery. They think if they strip it, they will get, let’s say, $3.40/lb. However, that is just the value of what you…

- What Size Separation System Do You Need?We want to discuss a common industry question: what size wire chopper should you get? When people first contact us, they often aim for the largest model like a C4 or C5, envisioning substantial chopping volumes and material handling. This inclination is understandable, especially if they already have a consistent…

- Is It Worth Prepping #2 Copper Pipe?About a decade ago, some customers visited us, including a couple of executives. As we passed by our alligator shear, one of them asked if they had any of those at their yards. The other executive mentioned they did have a few, but only at one of their facilities, despite…

- The Difference Between Granulators and Vertical Mills (& Turbo Mills)We want to discuss the distinctions between a granulator, vertical mill, and touch upon the turbo mill and their respective applications. Granulators and wire choppers have long been synonymous, typically used together for four decades or so. Over time, granulators have predominantly featured D2 steel blades in various blade configurations—staggered…

- How To Process: ACR Aluminum Copper RadiatorsWe get contacted a lot by people asking if they can use a wire chopper for processing aluminum-copper radiators. And, the answer is yes and no. There are several differences we use in our approach to processing aluminum-copper radiators. When dealing with aluminum-copper radiators, the deck of your screen can…