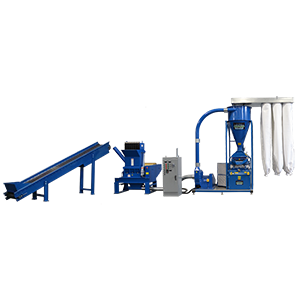

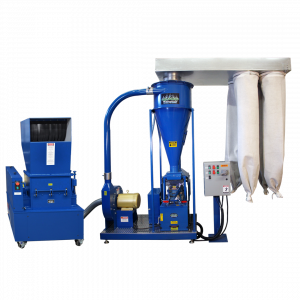

Scrap Metal Recycling

The #1 in Scrap Processing and Wire Chopping Solutions.

Over the last Decade, Cable Management has quickly taken first place as the fastest growing, best-selling recycling process manufacturer and integrator.

Contact Us to find out why.