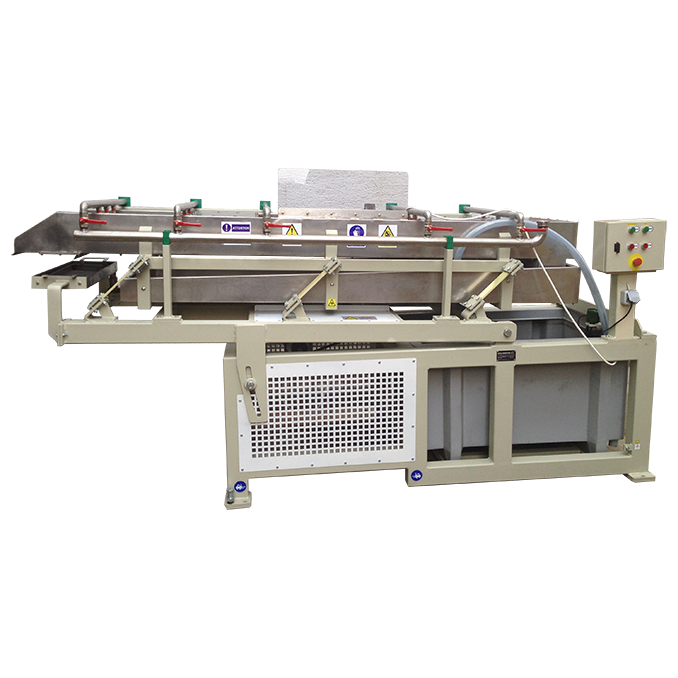

Wet Separator MM S2500-600

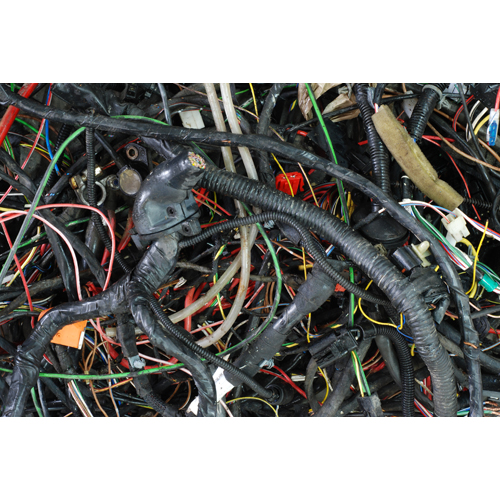

It is primarily designed for use in recycling of waste cables (used to separate copper or aluminium particles from plastic ones), but because of its unique design it is also applicable for the separation of different particles (eg. the electronic waste, the recycling of automobiles and industrial radiators, the recycling of batteries, catalysts, or for the separation of any two particles of different specific gravity).

A new version with double beds enables high throughput of material with very high purity of the obtained fractions (copper) and copper loss is reduced to zero. The machine is equally efficient in the separation of the granules obtained by grinding of solid cable and granules of so called hair wire

Unlike the dry separator, here in plastic there are no copper particles. Several companies bought it just to screen the plastic they got by recycling of cables with dry separator and thus additionally extracted copper from the plastic (up to 10%).

There are standard three sizes that can recycle 350 – 1000 kg of ground mass per hour, but on request there can be larger performances (the machine code is also the size of table).

The machine is extremely quiet and peaceful and is not it necessary to additionally be fixed on the ground (foundation). One can easily be built on your existing recycling line or we can offer you the cable granulator, and conveyor belt for material supplying from granulator to separator or from the separator.

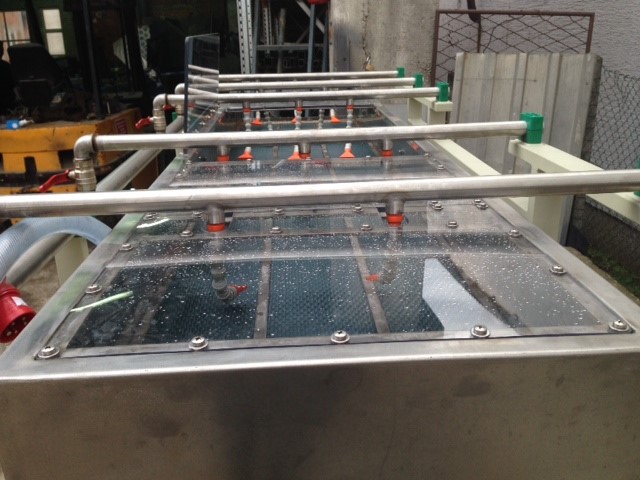

The machine has a water tank from which water is directed through the pump to adjustable nozzles and through a screen again returned to the reservoir (tank). Thus the same water is used continuously, it is only necessary to add a bit occasionally, and this is done automatically too by valve with a float. Water flow through the nozzles can be adjusted by valves, and the slope of the table can also be adjusted.

All parts in contact with water are made of pro-chrome (stainless steel- inox).

The main function of the machine:

Separation of metallic particles from non-metallic ones by different specific gravity of particles.

Because of differences in density (weight) heavier particles tend to go to the top, and lighter are washed away by water to a lower floor where it comes out again from machine. The machine therefore has two outputs, the upper one for heavier fractions (copper, aluminium) and lower for lighter ones (plastic, paper, nylon, …).

The machine differs from the similar products on the market by its great performance, very peaceful and quiet operating, low power consumption, compact design, high-quality and ruggedly constructed, and above all, very competitive price.