Wire Processors Want Three Things: To Increase Capacity, Be Able to Process Different Types of Material, and Maximize Revenue

We can help you upgrade your wire chopping system to match your materials and volumes and streamline your operation for maximum value.

Are You Looking to Maximize Your Processing Efforts?

Having multiple materials and not chopping each of them means you are leaving money on the table.

Without processing all of your materials:

- You have less control over your profit margins

- You are more exposed to shifting market conditions

- You have a narrower product offering, giving you limited access to markets

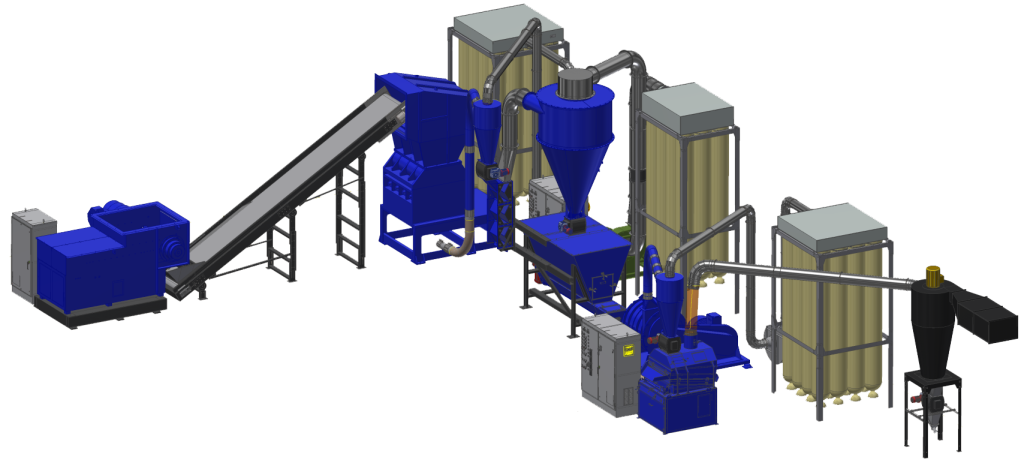

Wire Choppers and Cable Recycling Systems: Multiple Options Built to Match Your Processing Needs

Whether your volumes are in tons or truckloads, or you are processing more than one type of material, there are many configurations to meet your needs and expected growth.

✓ High Grade Wire Recovery

When the bulk of your processing will be focused on clean, uncontaminated #1 insulated copper. This includes wire like THHN, Romex®, feeders, and other high-yield cables.

✓ Low Grade Wire Recovery

For when you are going to be handling primarily low-yield wire or various types of plated copper, aiming at recovery from telco, hair wire, Christmas lights, steel BX/MC, and beyond.

✓ Mixed ICW Recovery

You have a mixed bag. There is a range of different materials you get in and are looking to separate the non-ferrous from each. When your volumes are consistent but the wire type may not be.

✓ Non-Ferrous Auto Recovery

Whether it takes the shape of aluminum-copper radiators, auto harness wire, auto shredder residue, or copper-bearing motors, you are focused on recovering non-ferrous and ferrous.

✓ Aluminum Wire Recovery

Your main source of incoming cable is insulated aluminum wire and you want to remove the insulation.

✓ Custom Recovery Solutions

Your specification needs are stringent, your materials are complex, and your volumes are high. Standard solutions are not an option, you are looking for something tailor-made for your operation.

Upgrade Your Wire Chopper in 3 Easy Steps

Determine the right size system and solutions to get your recycling operation to the next level.

Fill Out Our Request a Quote Form

Tell us about the existing equipment you have, what your pain points are, what you are planning to process, your current volumes, and other needs you are looking for in your line.

Evaluate Your Options With a Team Member

One of our professionals will reach out to you and conduct a thorough assessment, reviewing all potential solutions with you.

Stop Making Less From Your Wire

Getting full value for your materials does not have to be difficult. Our team is here to help provide an individualized wire chopping solution tailored to your current and future processing needs. We are dedicated to getting you the right system and available options for your business.

- How much does a wire chopper cost?How Much Does a Wire Chopper Actually Cost?Price is important. It is one of the many details we want to know when researching a potential…

- What Size Separation System Do You Need?We want to discuss a common industry question: what size wire chopper should you get? When people first contact us, they often aim for the…

- The Difference Between Granulators and Vertical Mills (& Turbo Mills)We want to discuss the distinctions between a granulator, vertical mill, and touch upon the turbo mill and their respective applications. Granulators and wire choppers…

- Is It Worth Chopping Cable? (part 2)We are moving forward with part two of evaluating whether it is worthwhile for you to chop your wire. We will start by putting some…

- Is It Worth Chopping Cable? (part 1)A question we often get is whether it is worthwhile to chop wire. This decision depends on several things, including your location, electricity costs, the…