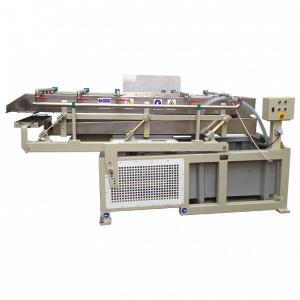

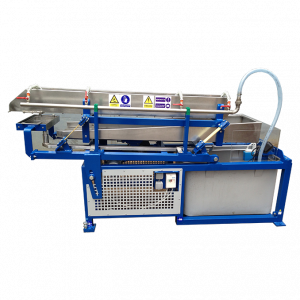

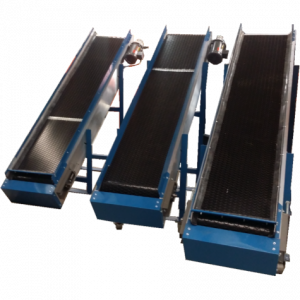

Plastic Recycling

Versatile systems for plastic granulation and separation.

Cable Management is your “one stop shop”, providing versatile equipment for both small and large recycling operations. Our modular systems can be expanded or upgraded as your business grows.

Contact Us so we can create a custom system for you.